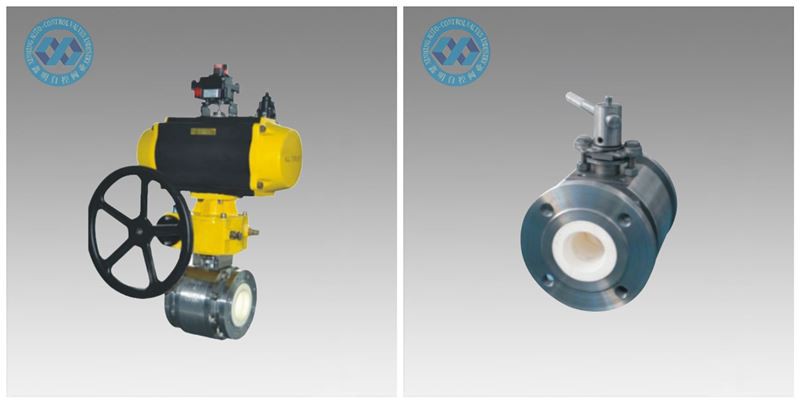

Product Introduction

High-strength forged steel ceramic ball valve can be selected for specific working conditions (A105N, SS304, SS316, SS316L and other materials, the three-stage structure design of this valve has high body strength, simple and reliable structure.

Ceramic ball valves are highly resistant to corrosion, which means that they are less likely to get damaged in corrosive environments. This advantage makes them ideal for use in industries such as oil and gas, chemical and petrochemical industries.

Ceramic ball valves are highly wear-resistant, which means that they can endure harsh environments and last for a long time without needing to be replaced. This advantage makes them a cost-effective solution for companies, as they reduce the maintenance costs associated with frequent replacements.

Ceramic ball valves have a low friction coefficient, which means that they operate smoothly and with minimal force. This results in less wear and tear on the valve and its components, leading to greater durability and longer service life.

Quick Details

Product Name: Ceramic ball valve

Nominal passage: DN15-250mm (2/1"-16")

Nominal pressure: PN1.0~4.0MPa (150~300Lb)

Applicable temperature: ≤300℃

Material: carbon steel, stainless steel, etc.

Medium: silica fume, coal, cinder, powdered particles, gypsum liquid,Sulfuric acid, hydrochloric acid, and other corrosive properties.

Widely used: opening and closing devices in power, petroleum, chemical and other road systems.

Features

1. High wear resistance: In addition to excellent corrosion resistance, structural ceramics also have extremely high hardness, up to HRA88 or even higher, second only to diamond, so the whole village ceramic ball valve in various wear and high erosion conditions Has the best performance.

2. High corrosion: The valve body, valve seat and internal cavity of the valve that are in direct contact with the medium are all made of ceramic structural materials; the ceramic has extremely high chemical properties. It hardly reacts with all chemical media, making ceramic ball valves suitable for most highly corrosive media.

Company Introduction

Since 2007,WUXI XINMING AUTO-CONTROL VALVES INDUSTRY CO., LTD has established.

We mainly manufacture Pneumatic Actuator, Pneumatic Ball Valve, Pneumatic Butterfly Valve, Pneumatic/Electrical Control Valve, etc.

Our company has advanced processing equipment and sophisticated testing equipment. Our processing equipment include lathes, milling machine, boring machine, planer, drilling machine, CNC lathes, CNC machining centers and other equipment. There are totally 30 sets, of which there are 5 sets imported vertical machine center and several sets advanced CNC lathes.

FAQ

Q 1: Payment terms capacity?

A 1: T/T, L/C, Western Union.

Q 2: Trade terms?

A 2: In according with Incoterms 2010, normally with EXW, FOB shanghai, CFR, CIF and DDU.

Q 3: Validity of quotation?

A 3: Within 30 days.

Q 4: Modes of shipment?

A 4: By sea, by air, by express, or by railway.

Q 5: Warranty?

A 5: One year quality warranty for free, and lifelong paid service.

Q 6: Installation and training?

A 6: normal video guidance for installation. If necessary, paid overseas engineering service provided.

Hot Tags: Ball Valve,Limit Switch Box,Solenoid Valve