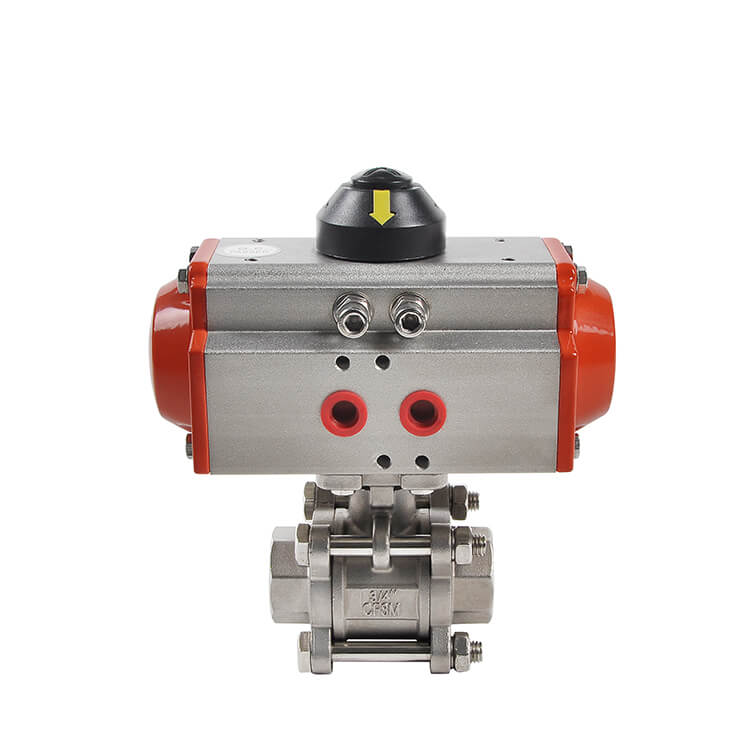

Yoke actuators are highly regarded for

their ease of maintenance and extended service life, which are significant

advantages in industrial applications.

The simple and robust design of yoke actuators

contributes to their low - maintenance nature. With a limited number of moving

parts such as the piston, diaphragm, and yoke mechanism, there are fewer

components that can potentially malfunction. This straightforward construction

allows maintenance technicians to quickly identify and address any issues. For

example, in the case of a minor piston seal leak, the accessible design enables

easy replacement without the need for complex disassembly procedures.

Materials used in yoke actuators also play

a crucial role in their durability. High - quality materials like stainless

steel for the housing and corrosion - resistant alloys for internal components

ensure resistance to harsh operating conditions. In environments with high

humidity or exposure to corrosive chemicals, these actuators can withstand the

elements, reducing the likelihood of wear and tear.

Furthermore, the operating principle of

yoke actuators, which often rely on the smooth transfer of force from the air

pressure to the valve, minimizes stress on components. This consistent and

controlled operation over time leads to a long service life. As a result,

industries such as oil and gas, where continuous operation is essential, can

rely on yoke actuators with confidence, knowing they require minimal

maintenance and can function reliably for extended periods.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com