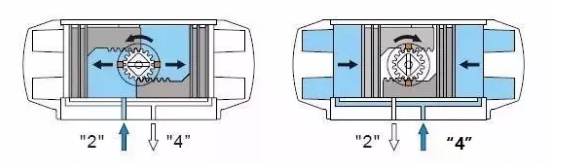

1. Working principle diagram of double acting pneumatic air actuator

When the air source pressure enters the middle chamber between the two pistons of the cylinder from the air port (2), the two pistons separate and move towards the two ends of the cylinder. The air in the two end chambers is discharged through the air port (4), and at the same time, the two piston racks synchronously drive the output shaft (gear) to rotate counterclockwise. On the contrary, when the air source pressure enters the air chambers at both ends of the cylinder from the air port (4), it causes the two pistons to move towards the middle of the cylinder, and the air in the middle chamber is discharged through the air port (2). At the same time, the two piston racks synchronously drive the output shaft (gear) to rotate clockwise. If the piston is installed in the opposite direction, the output shaft will rotate in the opposite direction

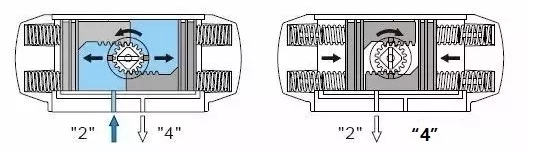

When the air source pressure enters the middle chamber between the two pistons of the cylinder from the air port (2), it causes the two pistons to separate and move towards the two ends of the cylinder, forcing the springs at both ends to compress. The air in the two end chambers is discharged through the air port (4), and at the same time, the two piston racks synchronously drive the output shaft (gear) to rotate counterclockwise. After the air source pressure passes through the solenoid valve, the two pistons of the cylinder move in the middle direction under the elastic force of the spring. The air in the middle chamber is discharged from the air port (2), and at the same time, the two piston racks synchronously drive the output shaft (gear) to rotate clockwise. If the piston is installed in the opposite direction, the output shaft will rotate in the opposite direction when the spring returns.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com