Pneumatic actuator valve specifications are

crucial for understanding and selecting the right valve for a specific

application. Here are the key aspects:

Valve size: Usually denoted by nominal

diameter, it determines the flow capacity. Larger sizes allow for higher flow

rates, but should be matched to the system's flow requirements to avoid

inefficiencies.

Pressure rating: Indicates the maximum

pressure the valve can handle safely. It must be greater than the maximum

operating pressure of the system to prevent leaks or damage.

Flow coefficient (Cv): Quantifies the

valve's flow - handling ability. A higher Cv value means the valve can pass

more fluid or gas for a given pressure drop.

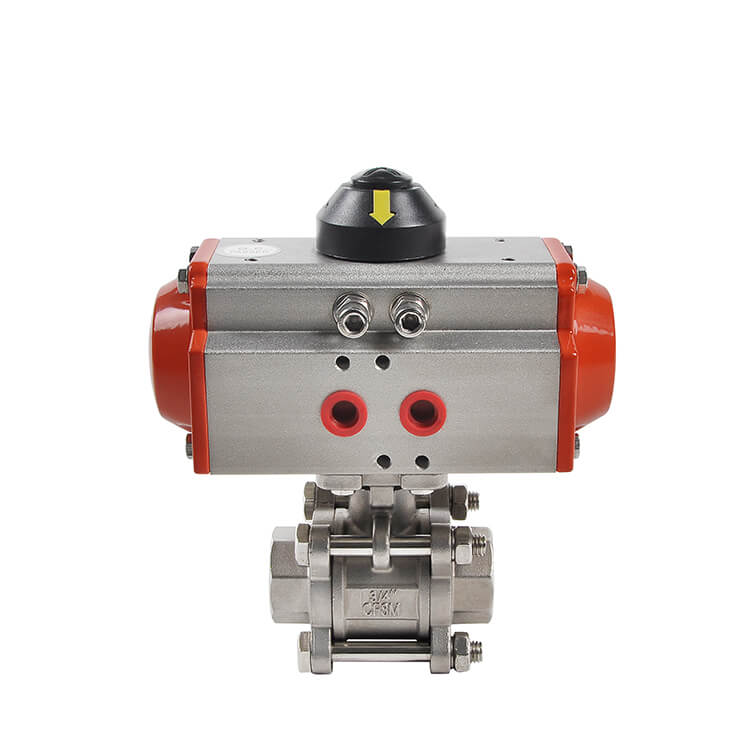

Actuator type and stroke: Piston - type

actuators offer high force, while diaphragm - type actuators provide more

precise control. The stroke length determines the extent of valve opening and

closing.

Control signal type: Common types include 4

- 20 mA analog signals and digital signals. The choice depends on the control

system available in the application.

Material of construction: The valve body,

actuator, and internal components can be made of various materials like stainless

steel, brass, or plastic. The material should be compatible with the fluid or

gas being handled to prevent corrosion and ensure long - term performance.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com