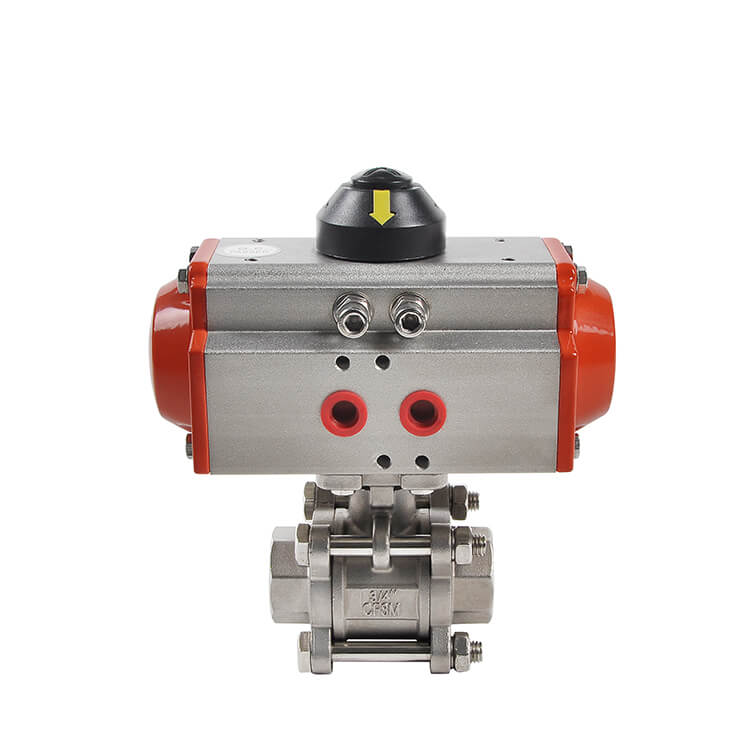

Here are the steps to calibrate a pneumatic

actuator valve for optimal performance:

Preparation: Ensure the valve is installed

correctly and the pneumatic actuator is connected properly. Check the air

supply system to make sure it provides stable pressure and clean air.

Zero - point calibration: With the valve in

the closed position, adjust the zero - point of the positioner or controller.

This is usually done by setting the output signal of the controller to the

minimum value that corresponds to the closed - valve position.

Full - scale calibration: Supply the

maximum air pressure to the actuator to open the valve fully. Then, adjust the

full - scale setting of the positioner or controller so that the valve reaches

its maximum opening position as indicated by the process requirements.

Intermediate - point calibration: Check and

adjust the valve position at several intermediate points between the fully

closed and fully open positions. This ensures that the valve responds

accurately and linearly to the control signals within its entire operating

range.

Fine - tuning: Observe the valve's

performance during actual operation and make any necessary fine - tuning

adjustments to optimize its response time, accuracy, and stability.

Documentation: Record all the calibration

settings and results for future reference and maintenance.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com