When choosing the right pneumatic actuator

valve for your system, several factors need to be considered:

Flow requirements: Determine the maximum

and minimum flow rates needed for your application. Consider the type of fluid

being handled, its viscosity, and the pressure drop across the valve. This will

help you select the appropriate valve size and flow coefficient (Cv) to ensure

efficient fluid flow.

Pressure rating: Check the operating

pressure of your system. The pneumatic actuator valve should have a pressure

rating that exceeds the maximum pressure in your system to ensure safe and

reliable operation.

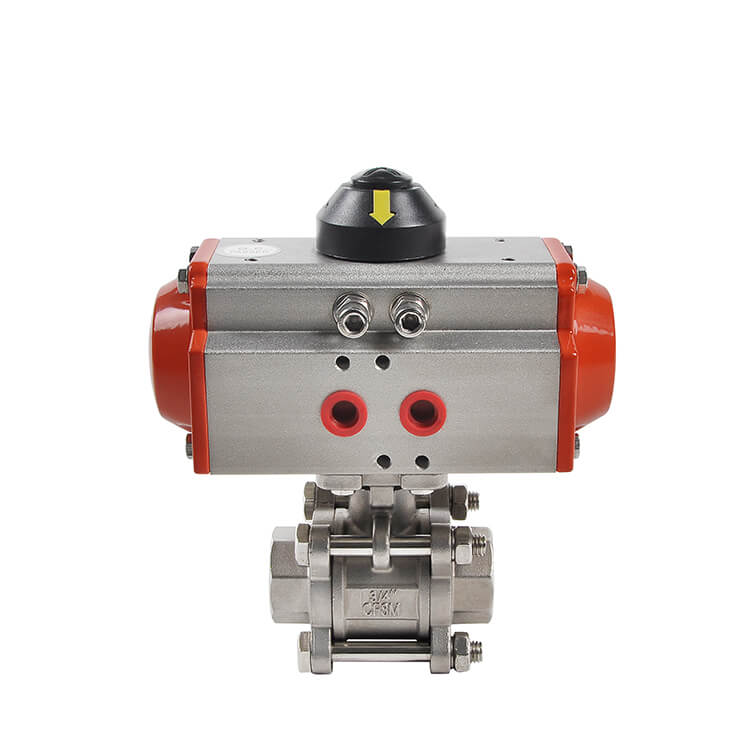

Actuator type: There are different types of

pneumatic actuators, such as piston - type and diaphragm - type. Piston - type

actuators are suitable for high - torque applications, while diaphragm - type

actuators are better for precise control and low - pressure applications.

Valve type: Select the appropriate valve

type based on your application. Common valve types include ball valves,

butterfly valves, and globe valves. Ball valves are good for quick - opening

and - closing applications, butterfly valves are suitable for large - diameter

pipelines, and globe valves offer precise flow control.

Control requirements: Consider whether you

need manual control, automatic control, or a combination of both. Also, think

about the type of control signal (e.g., 4 - 20 mA, digital) that your system

uses to operate the valve.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com