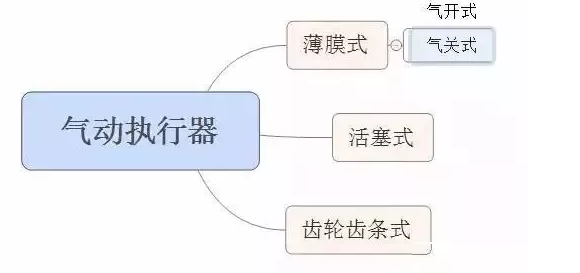

1. Thin film actuator

The membrane actuator is the most commonly used and can be used as a pushing device for general control valves, forming a pneumatic membrane actuator. The signal pressure p of the pneumatic diaphragm actuator acts on the diaphragm, causing it to deform and driving the push rod on the diaphragm to move, causing displacement of the valve core and changing the valve opening. It has a simple structure, low price, easy maintenance, and wide application.Pneumatic thin film actuators have two forms of positive and negative effects.

When the signal pressure from the controller or valve positioner increases, the downward movement of the valve stem is called a positive action actuator; When the signal pressure increases, the upward movement of the valve stem is called a reaction actuator. The signal pressure of the positive actuator is transmitted into the thin film chamber above the corrugated membrane; The signal pressure of the reaction actuator is transmitted into the thin film chamber below the corrugated membrane. By replacing individual parts, the two can be retrofitted to each other.

2. Piston type actuator

The pneumatic piston actuator moves the piston in the cylinder to generate thrust, and obviously, the output force of the piston type is much greater than that of the diaphragm type. Therefore, the thin film type is suitable for situations with low output and high accuracy; Piston type is suitable for applications with high output force, such as large-diameter, high-pressure drop control, or butterfly valve propulsion devices. In addition to membrane and piston types, there is also a type of long stroke actuator that has a long stroke and high torque, suitable for outputting angular displacement and large torque.

The signal standard received by the pneumatic actuator is 0.02 to 0.1 MPa.

The main components of pneumatic piston actuators are cylinders, pistons, and push rods. The piston inside the cylinder moves with the change of pressure difference on both sides of the cylinder. According to their characteristics, they are divided into two types: proportional and two-dimensional. The two position system pushes the piston from the high-pressure side to the low-pressure side based on the magnitude of the operating pressure on both sides of the input piston. Proportional type is a valve positioner added on the basis of the two position type, which makes the displacement of the push rod proportional to the signal pressure.

3. Gear rack actuator

Gear and rack type (double piston and rack type) pneumatic actuators have the characteristics of compact structure, beautiful appearance, fast response, stable operation, and long service life. All accessories adopt the most advanced anti-corrosion treatment technology, which can adapt to various harsh working conditions. Its high and low temperature, as well as various special stroke actuators, have shown good performance in various application fields.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com