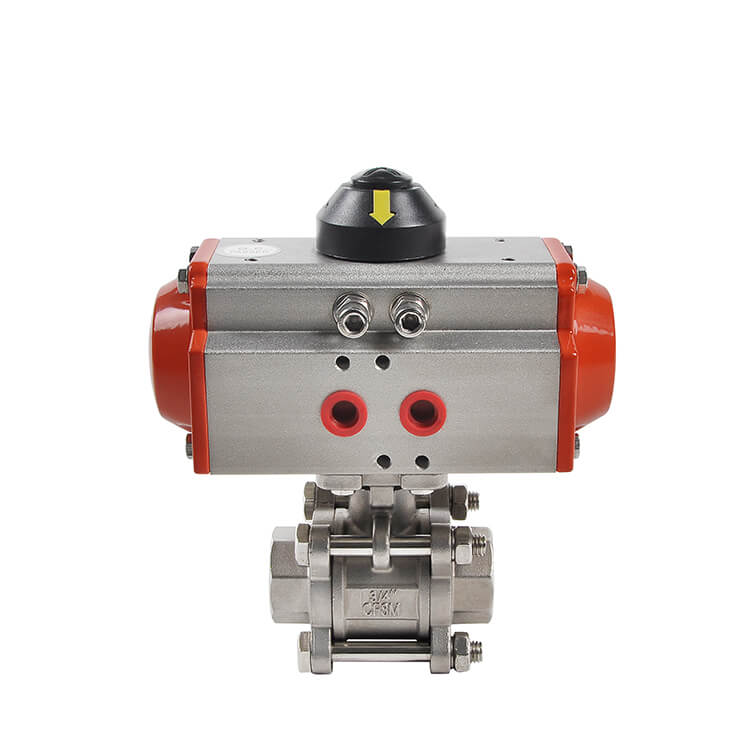

The yoke in actuators serves a critical

function by ensuring optimal force distribution, which is fundamental to the

efficient operation of these devices. In an actuator, the yoke acts as a

connecting and distributing element between the power source, such as a piston

or a motor, and the component it controls, typically a valve.

When force is generated, for instance, by

the pressure of compressed air acting on a piston in a pneumatic actuator, the

yoke comes into play. It is designed with a specific shape and structure that

enables it to evenly disperse this force. The yoke's geometry allows it to

translate the linear force from the piston into a rotational or oscillatory

motion that can effectively operate the valve. This even distribution of force

prevents any single part of the actuator or the valve from being subjected to

excessive stress.

Optimal force distribution achieved by the

yoke has several benefits. Firstly, it enhances the overall performance of the

actuator. The smooth transfer of force ensures precise control over the

movement of the valve, which is crucial in applications where accurate

regulation of fluid or gas flow is required. Secondly, it improves the

reliability of the system. By preventing overloading of components, the yoke

helps reduce the risk of premature wear and mechanical failures. This, in turn,

extends the service life of the actuator, making it a cost - effective choice

for industries like oil and gas, chemical processing, and power generation,

where continuous and reliable operation is essential.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com