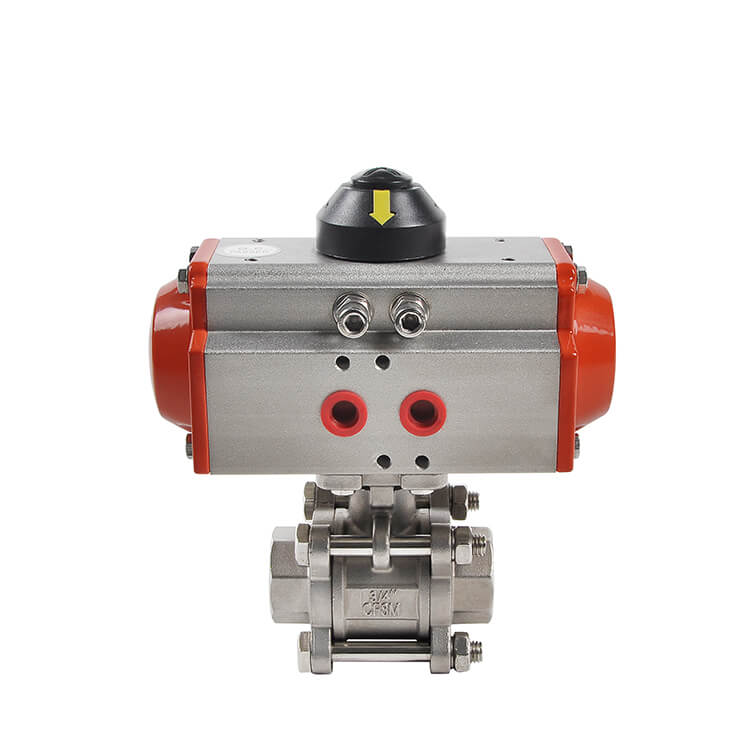

Regular maintenance is essential for

extending the lifespan of pneumatic actuator valves. These valves play a

crucial role in industrial fluid control systems, and their proper upkeep

ensures consistent and reliable performance.

One key aspect of maintenance involves

checking for air leaks. Leaky air connections can reduce the pressure supplied

to the actuator, leading to slower valve operation or even failure to fully

open or close. Regularly inspecting hoses, fittings, and seals and promptly

replacing any damaged components helps maintain optimal air pressure and

actuator efficiency.

Lubrication is also vital. Moving parts

within the actuator, such as pistons and gears, require proper lubrication to

reduce friction and wear. Using the recommended lubricants and applying them at

the specified intervals prevents excessive abrasion, ensuring smooth and

efficient operation over time.

In addition, periodic cleaning is

necessary. Dust, dirt, and debris can accumulate on the valve and actuator,

interfering with their performance. Cleaning these components not only removes

contaminants but also allows for early detection of potential issues like

corrosion or damage.

Finally, calibration and functional testing

should be part of the maintenance routine. Ensuring that the valve opens and

closes at the correct pressure and position helps maintain process control

accuracy and prevents unexpected breakdowns. By adhering to a regular

maintenance schedule, operators can safeguard the integrity of pneumatic

actuator valves and avoid costly repairs or replacements.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com