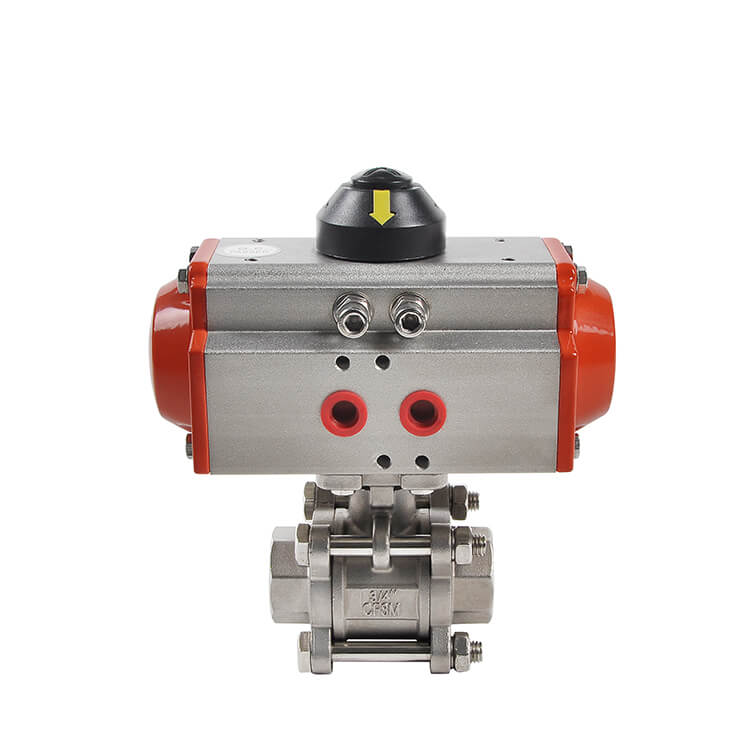

Pneumatic actuator valves are essential for

water treatment plant performance, playing a multi - faceted role in ensuring

efficient and reliable operations. These valves are critical for controlling

the flow of water and chemicals throughout the treatment process.

In the initial stages of water intake,

pneumatic actuator valves precisely regulate the amount of raw water entering

the treatment facility. Their quick response times allow for immediate

adjustments based on changing water levels or quality, preventing overflows or

shortages. During the treatment phases, such as filtration and disinfection,

these valves accurately control the injection of chemicals like coagulants and

disinfectants. The ability to adjust the valve opening and closing with

precision ensures the correct dosage is added, which is vital for effective

water purification.

Moreover, pneumatic actuator valves are

well - suited to the often - humid and corrosive environment of water treatment

plants. Their robust construction, typically with corrosion - resistant

materials and sealed components, enables them to withstand these harsh

conditions without frequent breakdowns. This durability reduces maintenance

requirements and downtime, keeping the water treatment process running

smoothly. Overall, by providing accurate flow control, chemical dosing, and

reliable operation, pneumatic actuator valves are indispensable for maintaining

high - quality water treatment and ensuring the consistent performance of water

treatment plants.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com