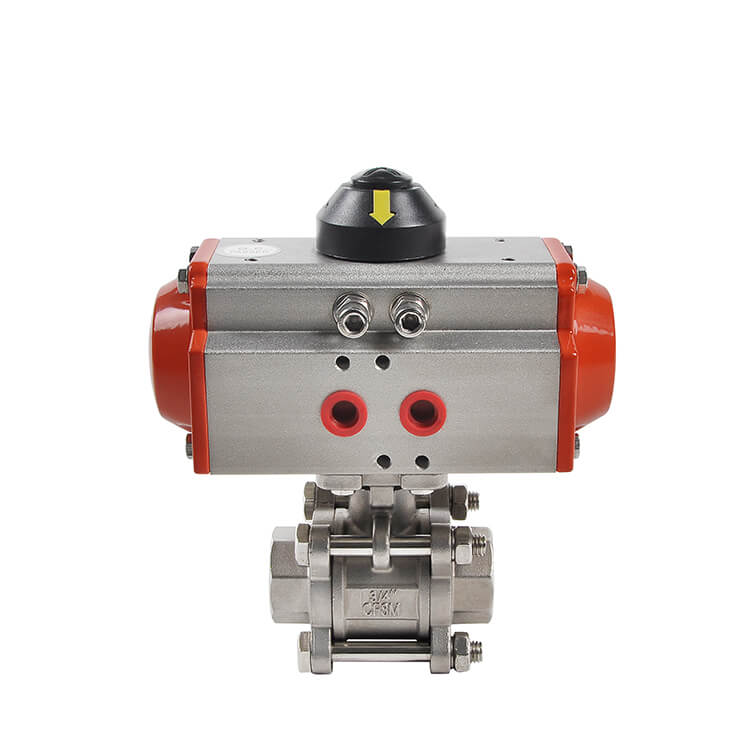

Pneumatic actuator valves offer significant

advantages in terms of integration into existing pipeline systems, thanks to

their adaptable design and straightforward installation requirements.

First, their modular structure simplifies

the integration process. Pneumatic actuators can be easily attached to a wide

range of valve types, such as ball, butterfly, and gate valves, which are

commonly found in pipeline systems. The standardized mounting interfaces ensure

compatibility with existing valves, reducing the need for complex modifications

or custom - made parts. This modularity allows for quick replacement of manual

valves with pneumatic - actuated versions, enabling automation without major

overhauls.

Second, the power source of pneumatic

actuator valves, compressed air, is often readily available in industrial

facilities. Existing air supply networks can be easily connected to the

actuators, eliminating the need for extensive electrical wiring or complex

power - generation systems. This not only streamlines the integration process

but also reduces installation costs and time.

Moreover, pneumatic actuator valves can be

controlled using simple and widely - available control systems. Basic pneumatic

control valves and solenoid valves can be used to regulate the air supply to

the actuators, allowing for seamless integration with existing control panels.

This simplicity makes it easy for operators to manage and monitor the valves,

ensuring smooth operation within the pipeline system. Overall, the ease of

integration makes pneumatic actuator valves a practical choice for upgrading

and optimizing pipeline systems.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com