Rotork, a global leader in valve automation, offers robust and innovative pneumatic actuators designed for precision, reliability, and safety in demanding industrial environments. Renowned for their durability and adaptability, Rotork pneumatic actuators are trusted across industries such as oil and gas, water treatment, power generation, and chemical processing.

Core Features

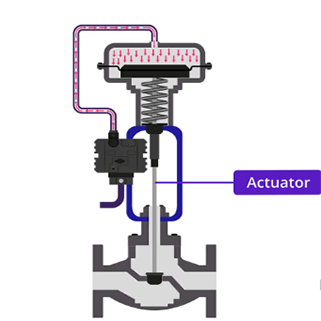

Rotork’s pneumatic actuator range, including the GP (Pneumatic) Series and CP (Compact) Range, combines advanced engineering with user-friendly design. These actuators convert compressed air into linear or rotary motion to control valves with exceptional accuracy. Key features include:

- High Torque Output: Capable of handling high-pressure and large valve applications.

- Fail-Safe Mechanisms: Spring-return or double-acting configurations ensure safe operation during power loss.

- Corrosion Resistance: Constructed with materials like stainless steel or epoxy-coated aluminum for harsh environments.

- Modular Design: Easy integration with valves compliant with ISO 5211 standards.

Industry-Specific Advantages

- Oil & Gas: ATEX/IECEx-certified actuators provide explosion-proof operation in hazardous zones.

- Water/Wastewater: Resistant to chlorine, sulfides, and moisture, ensuring longevity in treatment plants.

- Pharmaceuticals: Hygienic designs meet FDA and GMP standards for sterile processes.

- Power Plants: Withstand extreme temperatures and steam exposure in turbine bypass or boiler systems.

Smart Innovations

Rotork integrates cutting-edge technologies to enhance performance:

- IQ³ Multi-turn Actuators: Combine pneumatic power with digital control for real-time feedback and diagnostics.

- Pakscan™ Connectivity: Enable centralized monitoring and control via industrial networks.

- Eco-Friendly Designs: Optimize air consumption and support energy-efficient operations.

Applications

Rotork actuators automate critical valve functions, including:

- Pipeline isolation and pressure relief.

- Flow regulation in refining and chemical dosing.

- Emergency shutdown (ESD) systems.

Maintenance & Support

Rotork’s global service network ensures rapid maintenance, spare parts availability, and lifecycle support. Regular inspection of seals, springs, and positioners maximizes uptime.

Conclusion

Rotork pneumatic actuators exemplify engineering excellence, delivering unmatched reliability and adaptability for modern industrial automation. With a legacy of innovation and compliance with international standards, Rotork continues to drive efficiency and safety in mission-critical applications worldwide.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com