Introduction

Pneumatic rotary actuators play a crucial role in modern packaging machinery, offering precise motion control, high-speed operation, and durability. These actuators convert compressed air energy into rotary motion, making them ideal for applications such as capping, labeling, sorting, and filling in packaging lines.

How Pneumatic Rotary Actuators Work

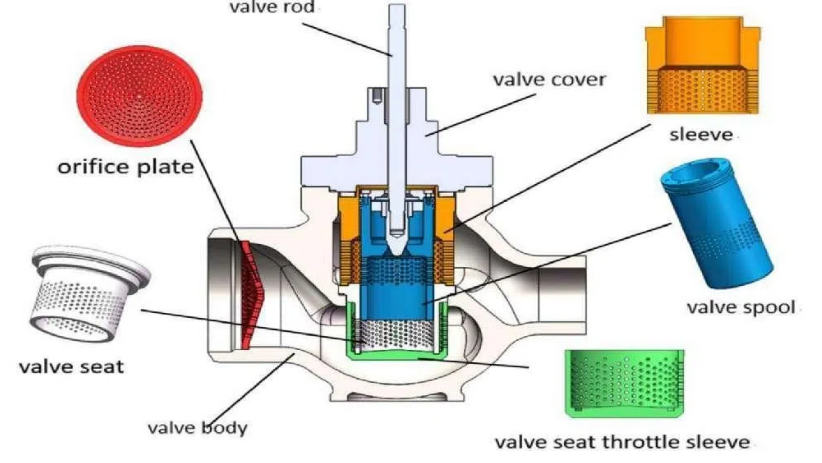

Pneumatic rotary actuators operate by using compressed air to drive a piston or vane mechanism, which then rotates a shaft. The key components include:

- Air inlet/outlet ports – Control the flow of compressed air.

- Piston or vane mechanism – Converts linear air pressure into rotary motion.

- Output shaft – Transfers torque to the connected machinery.

These actuators are available in different configurations, such as rack-and-pinion, vane-type, and helical designs, each suited for specific packaging applications.

Advantages in Packaging Machinery

- High Speed & Precision – Pneumatic actuators provide rapid rotational movement, essential for high-speed packaging lines.

- Durability & Low Maintenance – With fewer moving parts than electric actuators, they require minimal maintenance.

- Cost-Effective – They are generally more affordable than servo motors and hydraulic systems.

- Compact & Lightweight – Their small footprint allows easy integration into tight spaces.

- Safety & Reliability – No risk of overheating or electrical hazards, making them suitable for food and pharmaceutical packaging.

Common Applications in Packaging

- Bottle Capping & Sealing – Ensures consistent torque for secure closures.

- Labeling Machines – Rotates products for accurate label placement.

- Product Sorting & Conveying – Directs items to different packaging lanes.

- Filling Systems – Controls the rotation of nozzles for precise liquid or powder dispensing.

Conclusion

Pneumatic rotary actuators are indispensable in packaging machinery due to their efficiency, reliability, and cost-effectiveness. As packaging automation continues to evolve, these actuators will remain a key component in optimizing production speed and accuracy.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com