Pneumatic actuators are integral to heating, ventilation, and air conditioning (HVAC) systems, providing reliable control over airflow, temperature, and pressure in commercial, industrial, and residential buildings. By harnessing compressed air, these actuators ensure seamless automation of dampers, valves, and other components critical to maintaining indoor comfort and energy efficiency.

Role in HVAC Systems

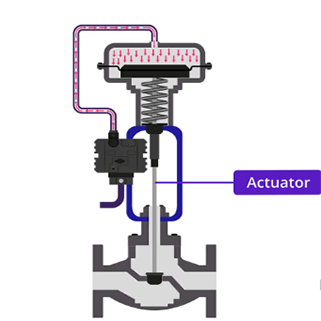

In HVAC applications, pneumatic actuators convert air pressure into mechanical motion to regulate devices such as:

- Air dampers for zone-specific airflow management.

- Cooling/heating valves in hydronic systems.

- Ventilation louvers to optimize fresh air intake.

-

Pressure relief valves in ductwork.

Their rapid response and fail-safe mechanisms (e.g., spring-return designs) guarantee uninterrupted operation, even during power disruptions.

Key Advantages

- Energy Efficiency: Low power consumption compared to electric actuators, reducing operational costs.

- Durability: Resistant to temperature fluctuations, humidity, and dust, ideal for harsh environments like rooftops or mechanical rooms.

- Cost-Effective: Simple design with minimal maintenance requirements and long service life.

- Safety: No electrical spark risk, suitable for hazardous areas or explosive atmospheres.

Applications Across HVAC Systems

- Variable Air Volume (VAV) Systems: Adjust dampers to balance airflow in real time.

- Boiler and Chiller Plants: Control water flow for temperature regulation.

- Cleanrooms and Hospitals: Maintain precise air pressure gradients to prevent contamination.

- Smart Buildings: Integrate with building management systems (BMS) for centralized automation.

Innovations Driving Performance

Modern HVAC pneumatic actuators incorporate smart sensors and digital positioners, enabling real-time feedback on valve position, pressure, and system health. IoT connectivity supports predictive maintenance and remote adjustments, aligning with smart building trends. Additionally, eco-friendly designs focus on reducing air consumption and compatibility with sustainable energy sources like solar-powered compressors.

Maintenance Tips

Regularly inspect seals, diaphragms, and air filters to prevent leaks and contamination. Ensure clean, dry air supply to avoid moisture-induced corrosion.

Conclusion

HVAC pneumatic actuators remain a cornerstone of efficient climate control, balancing precision, reliability, and cost-effectiveness. As the demand for smart, sustainable buildings grows, advancements in connectivity and energy optimization will further solidify their role in shaping the future of HVAC automation.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com