Festo’s DFPD Series pneumatic actuators are engineered to deliver high-performance motion control in demanding industrial and process automation applications. Combining compact design, energy efficiency, and exceptional reliability, these actuators are ideal for tasks requiring precise positioning, repeatability, and durability across sectors like manufacturing, food and beverage, pharmaceuticals, and robotics.

Design and Functionality

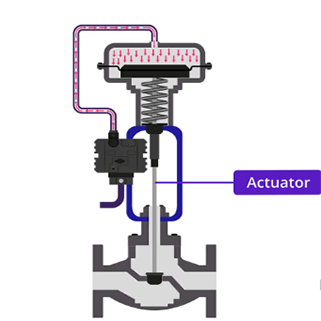

The DFPD Series features a double-acting or spring-return design, converting compressed air into linear motion to automate valves, grippers, and other mechanical components. Key attributes include:

- Compact and Lightweight: Space-saving design for integration into tight machinery layouts.

- High Repeatability: Precision-engineered pistons and seals ensure consistent performance in repetitive tasks.

- Corrosion-Resistant Materials: Stainless steel or anodized aluminum variants withstand harsh environments, including washdown areas.

- Adjustable Cushioning: Reduces impact at stroke endpoints, minimizing wear and noise.

Key Advantages

- Energy Efficiency: Optimized air consumption lowers operational costs and supports sustainability goals.

- Modular Flexibility: Compatible with Festo’s VUVG and other ISO-standard valves for seamless system integration.

- Low Maintenance: Robust construction and self-lubricating seals extend service intervals.

- Safety Compliance: ATEX-certified options available for explosive atmospheres.

Applications Across Industries

- Factory Automation: Control assembly line grippers, clamps, and feed systems.

- Process Control: Manage valves in chemical dosing, mixing, or pneumatic conveying.

- Packaging Machinery: Actuate filling, capping, or labeling devices with high-speed precision.

- Robotics: Enable precise motion in pick-and-place or material handling robots.

Smart Innovations

Festo equips the DFPD Series with advanced sensors and IO-Link compatibility, enabling real-time monitoring of position, pressure, and cycle counts. Integration with Festo’s Motion Terminal (VTEM) allows digital control of motion profiles, adapting actuator behavior dynamically via software. These features support Industry 4.0 initiatives, predictive maintenance, and energy optimization.

Maintenance Best Practices

- Use clean, dry air to prevent contamination.

- Periodically inspect seals and cushioning settings.

- Leverage Festo’s global service network for calibration and spare parts.

Conclusion

The Festo DFPD Series exemplifies innovation in pneumatic automation, offering unmatched precision, adaptability, and longevity. As industries prioritize smart manufacturing and energy efficiency, these actuators provide a future-proof solution for optimizing productivity and reducing downtime in dynamic environments.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com