Here's a concise summary of the key points about double-acting vs single-acting pneumatic valve actuators:

Single-Acting Actuators (Spring-Return)

- Operate with air pressure in one direction (open/close) and spring force in the opposite direction

- Offer fail-safe operation: automatically return to default position if power/air fails

- Best for safety-critical applications where valve position during failure matters

-

Drawbacks:

- Higher cost due to springs

- Springs wear out faster, reducing durability

- Larger physical size

-

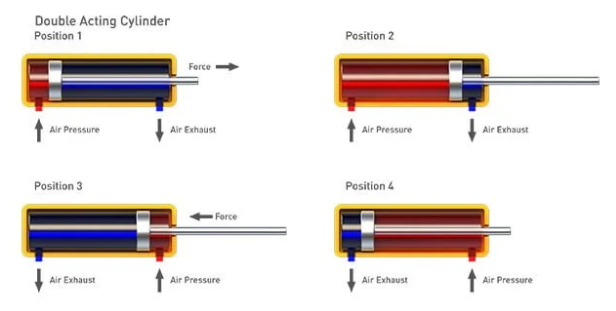

Double-Acting Actuators

- Use air pressure for both opening and closing motions

-

Advantages:

- Lower cost

- Longer lifespan (no springs to wear out)

- More compact design

- No inherent fail-safe capability (unless specially equipped)

- Ideal for high-cycle applications where fail-safe isn't critical

-

Innovation Option

- New double-acting actuators with integrated fail-safe (combines benefits of both types)

Selection Criteria

Choose single-acting when:

- Fail-safe operation is critical

- Cycle counts are moderate

- Size constraints allow it

Choose double-acting when:

- Cost and durability are priorities

- High cycling is needed

- Space is limited

- Fail-safe isn't required (or use new hybrid models)

For specific application advice, consulting with valve specialists like Gemini Valve is recommended.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com